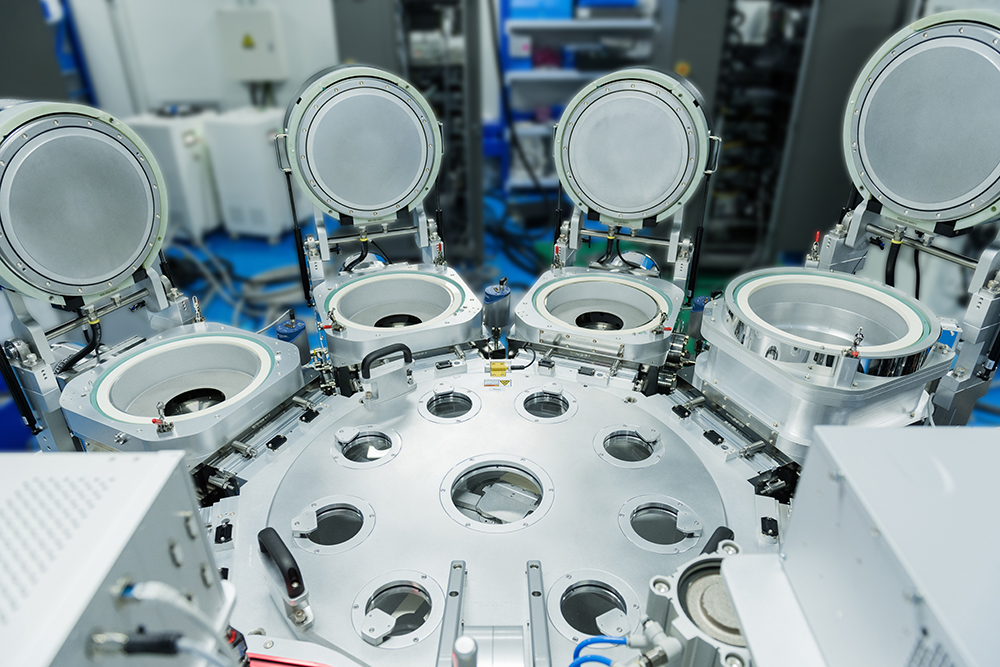

On Power Device market, SJI-SEMI are also famous on the front-side metal (FSM) Hot Al films sputtering by its excellent high AR hole-filling ability and planarization capability, and the AR ratio up to 3.5:1 @ 0.2um Bottom CD, is surpassing the imported equipment; in addition, SJI-SEMI’s back-side metal films sputtering (BSM) has stable performance and its productivity is nearly twice of the imported equipment’s, especially in the SiC power industry, our market share of FSM Hot Al and BSM is far ahead too.

With more than 20 years of experience in the IC industry, we have deep and diversified knowledge in many techniques such as high AR hole-filling, uniformity optimization, stress control, diversity and complexity of thin films.

Also, SJI-SEMI’s PECVD and ETCH equipment can directly replace the imported equipment in the MEMS, RF, Power and other semiconductor fields, and offer better process solutions.